AGRO PELLET

Energy source/ fuel

100% SOY STRAW PELLET

FOR INDUSTRIAL AND INDIVIDUAL USE

We produce high quality agro pellet from soybean dry stalk (straw) with a calorific value that meets the supply requirements of the industrial heating sector as well as electricity production, and it represents the best alternative to wood.

1. AGRO PELLET AS

INDUSTRIAL ENERGY SOURCE:

Usable:

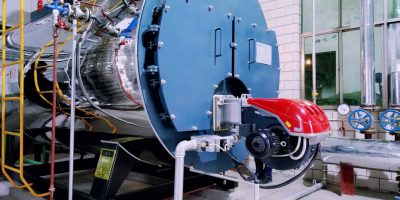

– in industrial plants,

– in power plants,

– in heating plants.

Advantages of use:

– renewable, reduces dependence on the use of fossil fuels (gas, oil and coal),

– homogeneous quality,

– increases the security of supply of energy sources from local fuel sources, with the possibility of concluding multi-year contracts and guaranteeing an unchanged price,

– available and easily accessible on the market,

– small price oscillations,

– sreduced emission of harmful gases during combustion,

– possible replacement of boilers or just burners in existing plants,

– easy for transportation and storage.

2. AGRO PELLET

AS FUEL:

Usable:

– for heating greenhouses and industrial plants,

– for heating commercial and individual buildings (schools, hospitals, apartments, houses),

– as a replacement for wood chips in special boilers of the Giles type.

Advantages of use:

– high thermal yield with rapid achievement of the desired strength and temperature, with a very low final ash residue,

– the most valuable alternative to the traditional heating fuels (constant demand and consumption growth),

– easily accessible, convenient for transport, ecological, economical and safe,

– clean (does not create dust during handling, which facilitates the maintenance of equipment and space).

Technical specification of agro pellets:

– Raw material composition: 100% soybean straw

– Calorific value: 17,500 kJ/kg

– Maximum ash content: 5.0%

– Maximum moisture content: 7.5%

Qualitative characteristics:

– cylindrical granules, with smooth and shiny surface (which is also an indicator of excellent quality),

– maximum length 40 mm,

– maximum diameter 6 mm,

– high-quality and highly calorific fuel,

– the most caloric in comparison with other agro pellets produced from agricultural biomass (because it gives the most energy), has the most intensive combustion and reaches the desired temperature the fastest,

– the utilization of thermal energy is over 90%, observed as energy values obtained per unit of product (for comparison, for coal and wood is a maximum of 70%),

– good density of granules and high combustion efficiency,

– minimum emission of harmful gases during combustion (CO2 and others), lower than the limit values,

– no additives such as resins, adhesives, plastics, metals and others.

WHY CHOOSE AGRO PELLET?

The continuity in the supply of quality raw materials

The production of the highest quality pellets begins with the selection of top quality raw materials, in our case dry straw. Straw, as a by-product of harvest, is a sustainable and environmentally friendly plant waste, which enables long-term and regular supply of pellet production from renewable energy sources/biomass. The location of our production plant in Bođani, at the source of the high-quality raw material base, greatly contributes to this goal, because the region is recognized as a leading place in the production of cereals in the Republic of Serbia.

The production from plant biomass in accordance with European norms

In our own factory, pellets are produced using advanced technology, which enables the production of an ecologically healthy product, without the addition of any additives, binders or chemical substances. In a short period of time we managed to reach the standards and norms established for the European and world market for pellets produced from biomass, soybean straw (EN 14961-6 and ISO 17225-6).

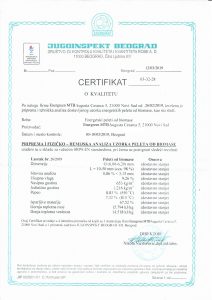

Confirmed quality

As a direct manufacturer, we guarantee stable quality, continuity in production and strict delivery time. The production cycle itself is strictly controlled and tested at each stage. Pellets are regularly tested (by random sampling method) on the moisture and ash content, as well as the energy value of heating, in order to ensure continuity in the quality of our products. We also examine the physical and chemical characteristics of pellets in accredited laboratories. We have certificates of physical and chemical testing of pellets and certificates of equipment. We place our production on the domestic market through direct sales, as well as on the European Union market.

Best value for money

KThe quality of pellets and affordable price, as well as guaranteed delivery times on request, throughout the year, enabled cooperation with large industrial facilities and the delivery of agro pellets from soybean straw as the main energy source.

Biomass converted into energy

The main tendency that occurs in many European countries is the accelerated development of biomass pellet production, which they use for the production of thermal energy in city heating plants, which represents the creation of multiple values.

Packing:

15 kg bags,

Big Bag 1000 kg

Delivery:

– in individual bags

– on pallets of 1050 kg (70 bags of 15 kg)

– possibility of arranging bulk delivery

Certificates

Proof of quality

FINSLAB

Institut BIOENERGIE Austria